Time-efficient structural design thanks to Open-BIM

In Bad Aibling, a spa town in the foothills of the Alps near Rosenheim, a gigantic new residential quarter will be built in three construction phases over the next few years. The engineering office concon from Traunstein was entrusted with the overall planning supervision of the construction project. In the project report, Florian Lindner, the responsible Structural Engineer, provides a detailed insight into the digital planning process, which was characterized by data exchange with open information models between CAD and calculation software.

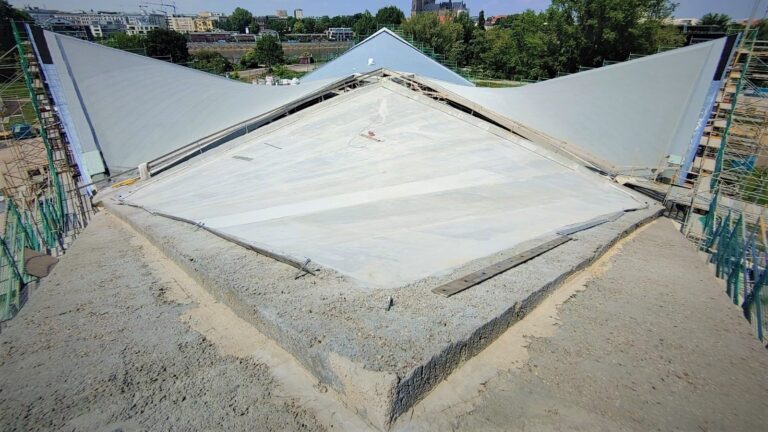

The residential complex “THE VIEW” offers space for 17 multi-family houses with a total of 193 condominiums on a total area of approx. 21,000 m² in the Harthausen district. A daycare center will also be part of the site. Construction phase 1 (4,490 m²) has already been underway since June 2022. For construction phase 2 (3,430 m²), the start of construction is planned for spring 2023. Together with the third construction phase (4,350 m²), this is based on a joint underground parking garage. While the engineering firm concon was responsible for the core competence structural design, reinforcement and formwork design as well as thermal and noise insulation for construction phase 1, the engineers were additionally commissioned with fire protection and GEG verification for the two subsequent phases. “Especially for such a large project, it makes sense that we have taken over the overall planning supervision for two of the three construction phases in order to optimize the planning process. Because all the planning comes from one office, we can work with maximum efficiency,” says Benjamin Di-Qual, who manages concon’s business together with Raphael Huber. Because all three construction phases were planned with buildings of building classes 3 and/or 4 and are therefore subject to inspection, the main task of the structural engineers was to create a verifiable and comprehensible structural analysis.

BIM par excellence

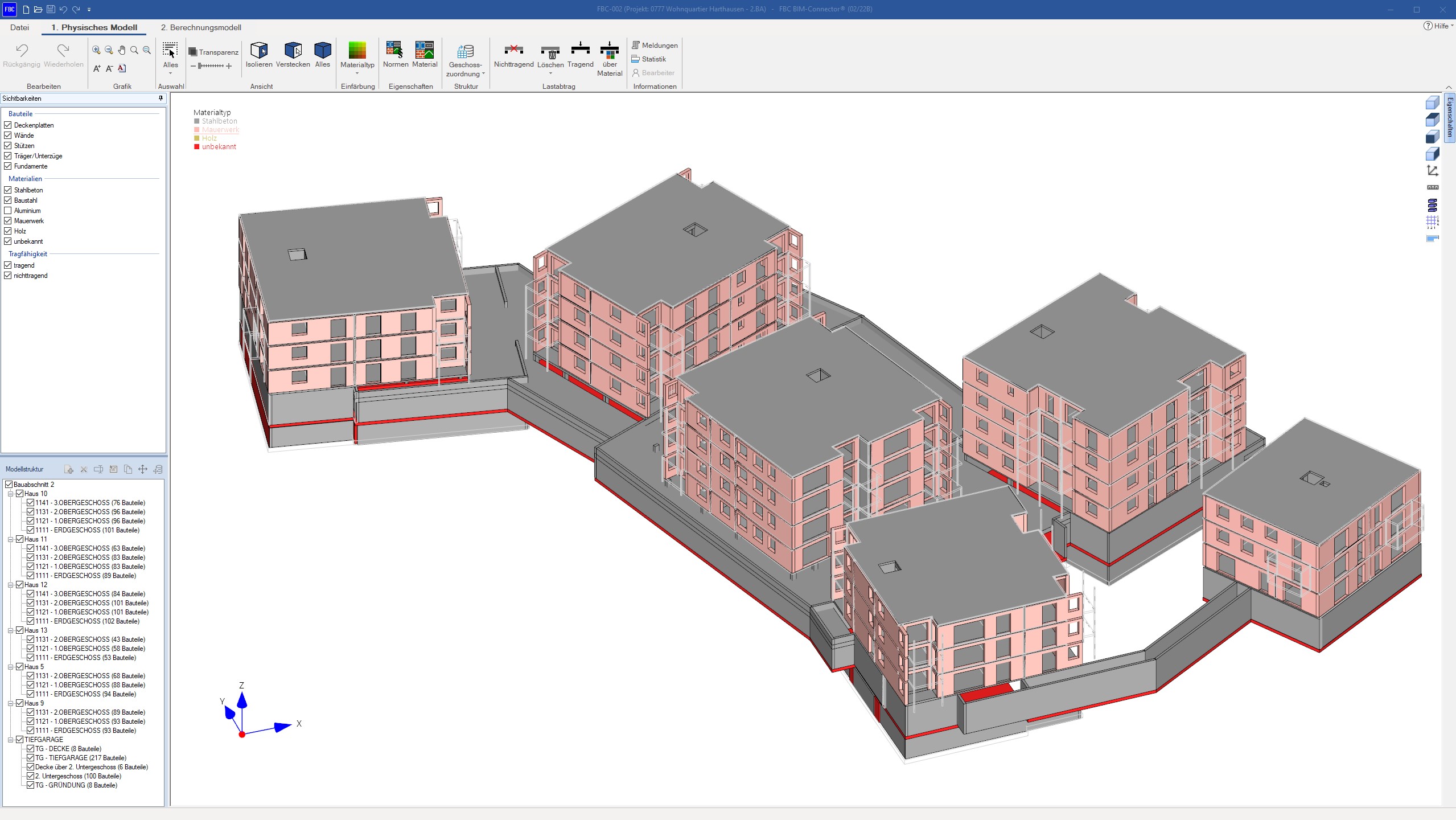

To ensure this, the engineering office from Traunstein resorted to FRILO as the sole structural calculation program. First, the data of the model, which had been created by the responsible architect’s office with Allplan, was transferred to the BIM-Connector via IFC file and integrated into FRILO in this way. There, Florian Lindner, who was in charge of the project, first reduced the model to the load-bearing components relevant for load transfer using the “Load transfer via material” function. “The assignment of load-bearing and non-load-bearing structures works quickly and reliably in the physical model. If the materials used are correctly classified by the architect, insulation, drywall and other elements that are inconsequential to my structural analysis can be removed simply by pressing a button. The BIM-Connector is a tremendous help when it comes to reducing a model from the architect to its load-bearing structures,” sums up the engineer. “Before working with the BIM-Connector, it would have taken me several days to manually enter a project of such dimensions into FRILO. Thanks to the automated model import via the BIM Connector, manual input is now eliminated. I was able to enter the upper floors of the six houses in just one day and check them for plausibility,” he explains the significant savings in working time. According to Lindner, the use of the BIM Connector makes sense for construction projects the size of a multi-family house.

The calculation model

Once the initial adjustments had been made, the structural engineer switched from the physical model to the calculation model in the BIM Connector, which automatically converted the solid elements into member and area elements. The functions provided in the calculation model allowed him to generate a correct structural model in no time at all. For example, the geometry of the calculation elements can be adjusted. Unconnected components can be connected, and walls can be disassembled. “Due to the different wall thicknesses between the masonry wall on the first floor and the wall made of reinforced concrete in the basement, in this project I had to manually move the outer walls in relation to each other to ensure a clean load transfer in the load-bearing axis. But that worked out great,” explains Lindner, adding, “The BIM Connector also solved requirements for more complex geometry such as height jumps extremely satisfactorily.” After all inputs had been checked in the calculation model and unfavorable component alignments had been corrected, Lindner moved on to the actual structural component design.

"For me, the interface to the GEO has enabled a correct, verifiable and comprehensible output document to the structural calculations. I am looking forward to using the BIM-Connector for future projects as well."

Florian Lindner, Structural Engineer at concon

The handover to the design programs

In the case of construction stage 2, he created a separate structural position for each of the six houses and determined the load transfer floor by floor house by house using FRILO’s GEO. A seventh model was generated for the underground parking garage. “To account for the load transfer from the building positions in the underground parking model, I transferred the loads from the six house models to the underground parking,” Lindner describes his procedure. Once the vertical load transfer for the entire construction section had been determined, the structural engineer controlled the corresponding FRILO programs for the design of individual components. Lindner calculated the slabs using the PLT Slab Program. For the calculation of the downstand beams, he used the Continuous Beam DLT. For the design of walls and columns, he made use of B5+. For those calculations, the geometries already predefined in GEO and the loads determined there were automatically transferred. Finally, DACH+ as well as HTM+ and HO1+ were used for the design of the roof truss. “THE VIEW was only my second project with the BIM Connector. Thanks to its clearly structured and concise user interface, I quickly found my way around. In addition, the interface to the GEO provided me with a correct, verifiable and traceable output document to the structural calculations. I am looking forward to using the BIM-Connector for future projects as well,” Lindner concludes positively.